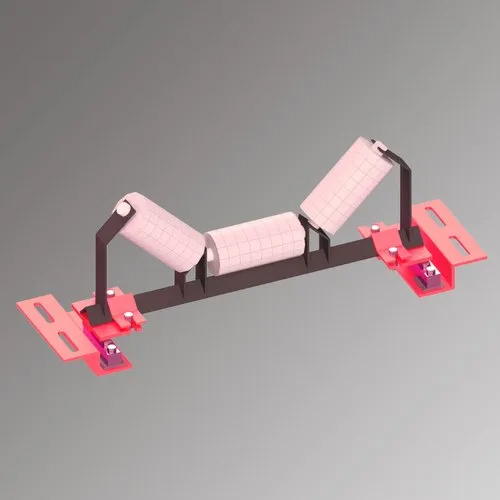

Conveyor Weighing System

Price 190000.0 INR/ Piece

Conveyor Weighing System Specification

- Usage

- Industrial Material Weighing on Conveyor Belts

- Display Type

- Seven Segment / LCD Display

- Power Source

- Electric Mains

- Size

- Customizable as per Conveyor Width

- Automatic Grade

- Automatic

- Function

- Continuous Weight Measurement

- Interface

- RS232 / RS485 Serial Interface

- Connectivity Type

- Wired / Optional Wireless

- IP Rating

- IP65

- Features

- Automatic Zero Tracking, Overload Protection

- Application

- Mining, Cement, Power Plants, Fertilizer, Aggregates, Bulk Material Handling

- Product Type

- Conveyor Weighing System

- Weighing Scale Type

- Belt Conveyor Weighing Scale

- Material

- Other

- Power Supply

- Electric

- Monitor Display

- Digital LCD/LED

- Color

- White

- Warranty

- Yes

- Mounting Type

- Inline with Standard Conveyor

- Alarm System

- Pre-set Overload Alarm

- Display Resolution

- 1 Kg, 10 Kg, or Custom

- Calibration

- Automatic and Manual Calibration Options

- Belt Speed Compatibility

- 0.1 m/s to 5 m/s

- Humidity Resistance

- Up to 95% Non-Condensing

- Sensor Type

- Strain Gauge Load Cell

- Operating Temperature Range

- -10C to +50C

- Maintenance Requirement

- Low, Easy Access Panels

- Controller Type

- Microprocessor-Based Controller

- Belt Width Supported

- 500 mm to 2000 mm

- Structural Finish

- Powder Coated / Painted

- Data Logging

- In-built with Export Facility

Conveyor Weighing System Trade Information

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 7-10 Days

About Conveyor Weighing System

Belt Scale Systems are precision weighing solutions designed to continuously measure the flow rate and totalized weight of bulk materials being transported on conveyor belts. These systems are widely used in industries such as mining, cement, steel, power plants, ports, and process industries where accurate material measurement is critical.

Key Features:

-

High Accuracy: Advanced load cell technology ensures accurate and reliable measurements even in harsh industrial environments.

-

Robust Construction: Designed for heavy-duty applications with rugged frames and weather-resistant components.

-

Digital Commu-nication: Equipped with modern protocols (Modbus, Profibus, Ethernet/IP, etc.) for seamless plant integration.

-

Real-Time Monitoring: Flow rate and cumulative totals are continuously displayed and logged for process optimization.

-

Easy Maintenance: Modular design for quick installation, calibration, and servicing.

-

Control Interface: Touch-screen controllers (typically 5"7") for user-friendly operation and diagnostics.

-

Integration Ready: Compatible with SCADA/DCS systems for centralized monitoring and control.

Reliable Inline Weighing Solution

Mounted directly on standard conveyor systems, this solution delivers robust, inline weight monitoring. Its industrial-grade design, including powder-coated components, allows deployment in tough environments such as mines, cement factories, and bulk material sites. Automatic grade features facilitate seamless operation and integration into existing workflows with minimal downtime.

Advanced Performance & Data Handling

The systems microprocessor-based controller and in-built data logging facilitate meticulous tracking of material flow. Users can export data for further analysis, ensuring effective process optimization and regulatory compliance. Overload alarms and automatic grade functions enhance operational safety and accuracy without interrupting regular production.

Flexible Configuration & Connectivity

Capable of supporting belt speeds from 0.1 m/s to 5 m/s and customizable widths, this conveyor scale adapts to diverse industrial requirements. The IP65-rated enclosure offers protection against dust and water, while the RS232/RS485 interface plus optional wireless connectivity make integration with plant control systems both straightforward and future-proof.

FAQs of Conveyor Weighing System:

Q: How is the Conveyor Weighing System installed on existing conveyors?

A: The weighing system is mounted inline with standard conveyor setups using easy-access panels, making installation straightforward and minimizing system disruption. Its customizable frame suits belt widths from 500 mm up to 2000 mm, providing flexibility for most industrial conveyor designs.Q: What is the process for calibrating the conveyor weighing scale?

A: Calibration can be performed either automatically or manually. The systems microprocessor controller guides users through a step-by-step calibration process, ensuring high accuracy (0.5% or better) is maintained for all material loads and flow conditions.Q: Where is this weighing system typically used?

A: This solution is widely deployed in industries such as mining, cement plants, fertilizer factories, aggregates production, and any bulk material handling facilities. Its rugged build and environmental resistance make it suitable for both indoor and outdoor installations across India and export markets.Q: What benefits does data logging and export provide for industrial users?

A: In-built data logging enables tracking of production flow and load histories, which can be exported for compliance, quality control, and workflow optimization. This supports informed decision-making and enhances operational transparency for manufacturers and suppliers.Q: When should overload alarms and automatic zero tracking be utilized?

A: Preset overload alarms provide immediate notification if conveyor loads exceed thresholds, helping to prevent equipment damage and material loss. Automatic zero tracking ensures the system maintains accurate weighing, especially during continuous operation and variable belt loads.Q: What type of display and connectivity does the system offer?

A: Users can choose between seven-segment LED displays or digital LCD screens for monitoring. The system features RS232/RS485 serial interface for data commu-nication, with optional wireless connectivity to easily integrate with control centers and remote monitoring systems.Q: How does the weighing system maintain reliable performance in extreme conditions?

A: Its structural components are powder coated or painted for protection, and the enclosure is rated IP65 for dust and water resistance. This ensures consistent performance in harsh environments, withstanding temperatures from -10C to +50C and humidity up to 95% non-condensing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Conveyor Belt Scales Category

Conveyor Belt Scale

Price 180000 INR / Piece

Minimum Order Quantity : 1 Piece

Power Source : Electric

Weighing Scale Type : Other, Digital

Warranty : Yes

Power Supply : 110240V AC, 50/60Hz

Dynamic Belt Scales

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Power Source : Electric

Weighing Scale Type : Other, Belt Weighing Scale

Warranty : Yes

Power Supply : 220240 V AC, 50/60 Hz

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese