Online Billet Weighing System

Price 400000 INR/ Kilograms

MOQ : 1 Kilograms

Online Billet Weighing System Specification

- Battery Life

- Optional Battery Backup, Up to 8 hours

- Power Source

- Electric

- Interface

- RS232, Ethernet

- Automatic Grade

- Automatic

- IP Rating

- IP65

- Display Type

- Digital

- Size

- Customizable as per Conveyor Size

- Features

- Real-time Data, High-Temperature Resistant, Conveyor Integration

- Application

- Steel Industry, Metallurgical Plants

- Usage

- Billet/Metal Weighing in Steel Plants

- Connectivity Type

- Wired

- Function

- Automatic Billet Weight Measurement

- Product Type

- Online Billet Weighing

- Weighing Scale Type

- Industrial Conveyor Scale

- Material

- Steel

- Power Supply

- 230V AC, 50/60 Hz

- Monitor Display

- Digital LCD/LED Display

- Load

- Up to 120 Tonnes

- Accuracy

- 1 %

- Capacity Range

- 1 Ton to 120 Ton

- Color

- Sliver

- Warranty

- 1 Year

- Belt Speed Compatibility

- Up to 2 m/s

- Construction

- Rugged, Vibration Resistant

- Software Support

- PC Connectivity with Reporting Software

- Calibration

- Fully Electronic On-site

- Alarm System

- Audio Visual Alerts for Overload

- Operating Temperature

- Up to 1200C Material Handling

- Mounting Type

- Integrated on Conveyor Line

- Resolution

- Display up to 10 kg division

- Data Logging

- Internal Storage and Data Export Facility

- Communication Protocols

- MODBUS, Profibus Compatible

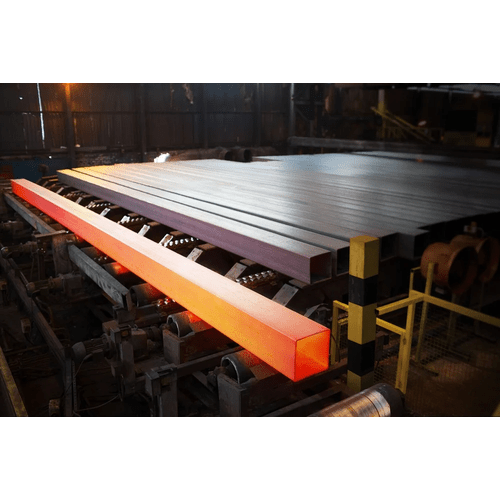

About Online Billet Weighing System

An online billet weighing system is a technology used in manufacturing and metal processing industries to accurately measure the weight of billets during various stages of production. Billets are typically semi-finished metal products that are later processed into final products like rods, bars, or other shapes. The online billet weighing system helps ensure the quality and consistency of the production process by providing real-time weight measurements.

Here are some key components and features typically associated with an online billet weighing system:

1. Load Cells:

Load cells are the primary sensors used to measure the weight of the billets. These cells convert the force exerted by the billet into an electrical signal, which is then used to determine the weight.

2. Conveyor System:

Billets are often transported on conveyor systems within the production line. The weighing system is integrated into these conveyors to measure the weight as the billets move through the process.

3. Data Acquisition System:

The system includes a data acquisition unit that collects and processes the signals from the load cells. This unit is responsible for converting the analog signals into digital data for further analysis.

4. Control Unit:

A control unit manages the overall operation of the weighing system. It may include a human-machine interface (HMI) for operators to monitor the weight measurements, set parameters, and make adjustments.

5. Software Integration:

The online billet weighing system is often integrated into the larger manufacturing or process control software. This integration allows for real-time monitoring, data logging, and analysis of the weight data.

6. Accuracy and Calibration:

Calibration procedures are essential to maintain the accuracy of the weighing system. Regular calibration ensures that the system provides precise and reliable weight measurements over time.

7. Automated Feedback and Control:

Depending on the application, the system may be integrated with feedback mechanisms to automatically adjust other parameters in the production process based on the weight measurements.

8. Data Logging and Reporting:

The system may have capabilities for logging weight data over time, generating reports, and providing historical records. This data can be valuable for quality control and process optimization.

Advanced Material Handling for Extreme Conditions

Engineered for steel plants and metallurgical environments, this weighing system operates efficiently at temperatures up to 1200C. Its robust steel construction and IP65 rating make it resistant to vibration, dust, and moisture, ensuring reliable performance even in the harshest settings.

Precise Weighing and Real-Time Data Management

With digital display resolution up to 10 kg and 1% accuracy, the system provides trustworthy billet measurements on conveyor lines. Real-time data logging, internal storage, and export features, as well as MODBUS, Profibus, Ethernet, and RS232 compatibility, support streamlined process control and traceability.

Seamless Integration and Flexible Operation

Designed for easy installation on existing or new conveyor lines, the system offers full automation, customizable sizing, and a high-speed weighing capability up to 2 m/s. Calibration can be performed electronically on-site, minimizing downtime and supporting efficient plant workflows.

FAQ's of Online Billet Weighing System:

Q: How does the Online Billet Weighing System operate in high-temperature environments?

A: The system is specifically engineered to withstand operating temperatures up to 1200C, thanks to its rugged steel construction and vibration-resistant design. It integrates directly on the conveyor line, ensuring continuous accurate weight measurement of hot billets in steel and metallurgical plants.Q: What is the process for installing and calibrating the system?

A: Installation involves integrating the unit onto your conveyor line, which can be customized to fit existing setups. Calibration is fully electronic and performed on-site, enabling quick setup and ensuring precise measurements without extensive downtime.Q: When and where is this weighing system most effectively used?

A: This system is best suited for steel industry and metallurgical plant environments, especially where automated, high-temperature material handling is common. It's ideal for processes requiring real-time monitoring and accurate record-keeping of billet weights.Q: What kind of data management and export capabilities does the system provide?

A: The weighing system supports internal data logging and offers data export through MODBUS, Profibus, RS232, and Ethernet protocols. Real-time data can be accessed through PC connectivity, and dedicated reporting software is provided for easy management and analysis.Q: How does the alarm system work for overload conditions?

A: If an overload is detected (when weight exceeds set capacity, up to 120 tonnes), the system triggers both audio and visual alarms. This immediate notification ensures safe operation and protects both the equipment and the material on the conveyor.Q: What are the main benefits of using this billet weighing system?

A: The main advantages include high-accuracy real-time weight monitoring, streamlined data handling, automation, robust construction for harsh environments, quick setup and calibration, overload protection, and customizable configurations to fit a range of industrial applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

In Domestic Area, We are mainly dealing in Andhra Pradesh, Delhi, Goa, Karnataka, Kerala, Maharashtra, Tamil Nadu, Telangana.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese